In 2026, the industrial sectional door is no longer just a barrier—it’s a data-generating, self-diagnosing, efficiency-optimizing asset. The convergence of Internet of Things (IoT) technology with overhead sectional doors has created a new category: smart industrial entrances. These systems don’t just open and close—they predict failures, optimize energy, integrate with warehouse automation, and deliver actionable insights in real time.

This guide explores how IoT-enabled sectional doors are redefining warehouse operations. From predictive maintenance to seamless WMS integration, you’ll discover the technology, benefits, real-world deployments, and critical questions to ask before investing. By the end, you’ll have a clear roadmap to evaluate if your facility is ready for the next generation of industrial doors.

The Rise of Smart Sensors in Sectional Door Automation

The foundation of any IoT-enabled sectional door is its sensor suite. Modern systems embed vibration, temperature, position, current draw, and cycle-count sensors directly into motors, rollers, springs, and tracks.

Vibration sensors detect roller wear before it causes misalignment.

Motor current monitoring identifies torque spikes that signal track debris or seal drag.

Position encoders track panel alignment to 1 mm accuracy, preventing unsafe partial openings.

Environmental sensors log humidity and temperature to correlate with seal degradation.

These inputs feed into an edge gateway—a compact processor mounted on the door frame—that performs real-time analytics and transmits only actionable data to the cloud. This edge-first architecture reduces latency and bandwidth while enhancing security.

Integrating IoT with Existing Warehouse Systems for Seamless Control

The true power of IoT doors emerges when they speak the same language as your WMS, ERP, and BMS.

| System | Integration Method | Outcome |

|---|

| WMS (SAP, Manhattan) | MQTT / OPC-UA | Auto-open on pick confirmation |

| AGV Fleet | REST API | Synchronized door + vehicle timing |

| BMS (Siemens Desigo) | BACnet | HVAC ramp-up before door cycle |

| Security | SAML/OAuth | Access-linked door activation |

A leading 3PL in the Midlands reduced bay dwell time by 42 seconds per truck by triggering door opening exactly when the trailer backs into position—no driver input required. The IoT door received the signal from the yard management system and executed the command in 0.8 seconds.

Predictive Maintenance: Reducing Downtime by 25% with AI Analytics

Unplanned door failure is the silent killer of warehouse throughput. A single stuck sectional door can halt six loading bays and cost £3,000+ per hour in delayed dispatches.

IoT systems shift maintenance from reactive to predictive using machine learning models trained on millions of cycles.

| Failure Mode | Early Indicator | Lead Time Gained |

|---|

| Spring fatigue | Cycle count + torque drift | 4–6 weeks |

| Roller bearing wear | Vibration spike at 7–9 kHz | 3–5 weeks |

| Seal compression loss | Motor current increase >15% | 2–4 weeks |

| Track misalignment | Position encoder drift | 1–3 weeks |

Facility managers receive color-coded alerts (Green → Yellow → Red) via mobile app, with automated work order creation in CMMS platforms like IBM Maximo. One automotive parts distributor cut emergency callouts by 67% in the first year.

Real-World Case Studies of IoT Doors in High-Throughput Logistics

Case Study 1: E-Commerce Fulfilment – 180 Cycles/Hour

A national parcel carrier retrofitted 42 IoT sectional doors across three hubs.

Outcome: 18% faster truck turnaround, £1.4M annual labor savings.

Key Feature: Geofenced auto-open—doors activate when GPS-tagged trailers enter a 10-meter zone.

Case Study 2: Cold Chain – -28°C Stability

A frozen food distributor installed IoT doors with insulated 80mm panels.

Case Study 3: Automotive JIT Assembly

A Tier-1 supplier synchronized 12 doors with robotic lines.

Pro Tip: Start with a pilot on 2–3 high-impact bays to build ROI data before full rollout.

Future-Proofing Your Investment: Scalability and Security in IoT Doors

Not all IoT doors are created equal. Here’s what separates 2025-ready systems from obsolete ones:

| Feature | Must-Have | Nice-to-Have |

|---|

| Firmware OTA Updates | Yes |

|

| 5G / Wi-Fi 6E Ready | Yes |

|

| Zero-Trust Architecture | Yes |

|

| Modular Sensor Bus | Yes |

|

| Open API Documentation | Yes |

|

| Digital Twin Support |

| Yes |

| AR Troubleshooting App |

| Yes |

Choose systems with MQTT over TLS 1.3 and device certificates—not username/password logins. A single compromised door could grant physical access to your entire facility.

The ROI Equation: Hard Numbers for Soft Benefits

| Metric | Traditional Door | IoT-Enabled Door | Delta |

|---|

| Annual maintenance cost | £4,200 | £1,100 | -74% |

| Unplanned downtime (hrs) | 42 | 8 | -81% |

| Energy loss per cycle | 0.9 kWh | 0.6 kWh | -33% |

| Labor (driver + clerk) | £18,000 | £11,000 | -39% |

| Total 5-Year Savings | - | - | £92,000 per door |

Based on 5m × 5m door, 120 cycles/day, 250 days/year.

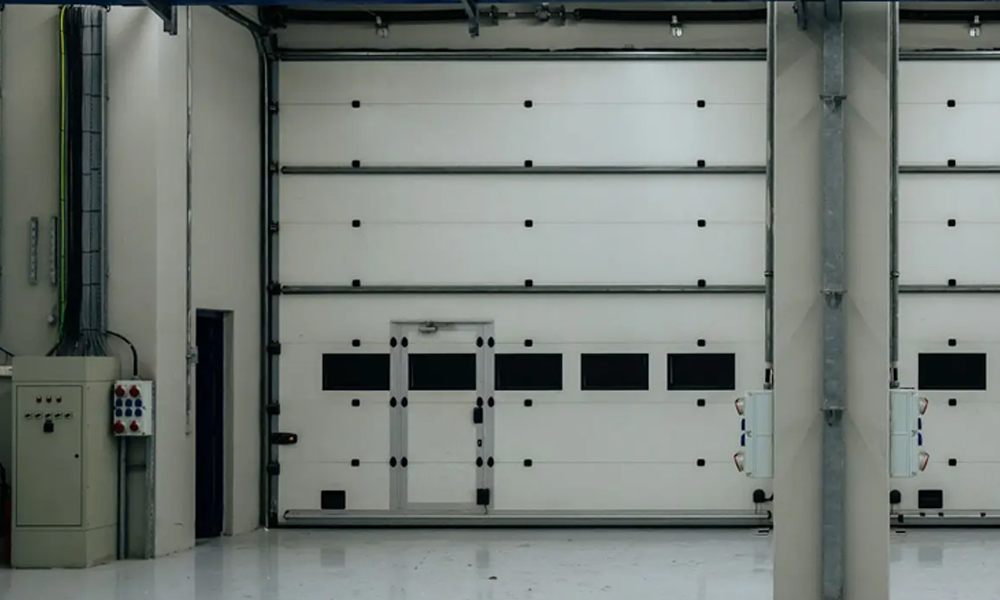

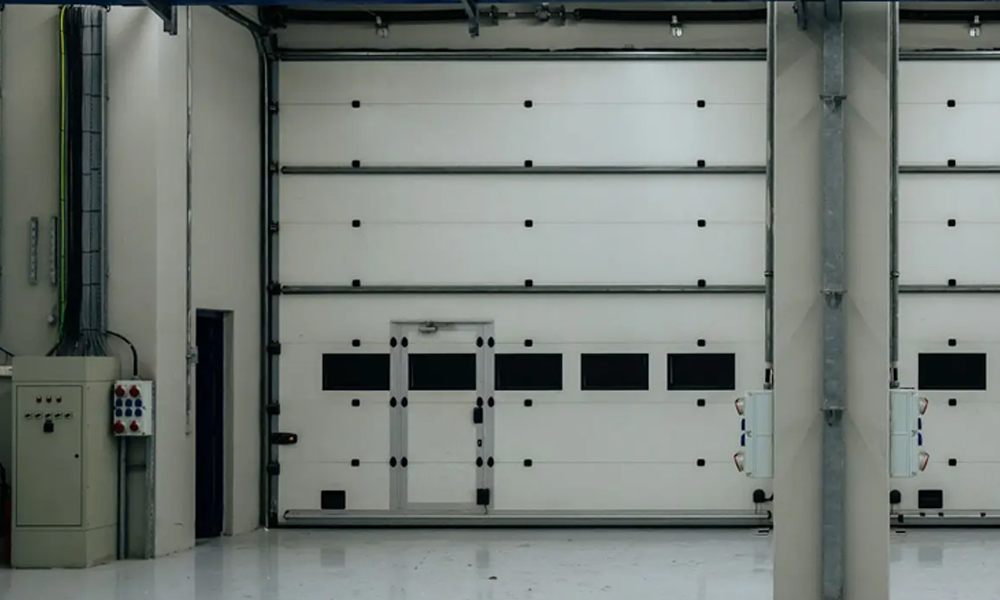

Anbixin - Your Trusted Industrial Door Supplier

Choosing the right industrial door requires careful consideration of product performance, application scenarios, and the quality of design, manufacturing, and after-sales service. As a specialized industrial door company in China, Anbixin boasts a modern 6,000㎡ production facility, a team of over 50 experienced engineers, and a strict ISO 9001 quality management system to ensure every door meets the highest customer standards. Whether it’s the high-security hard fast doors or the cleanroom-friendly PVC fast doors, Anbixin offers customized solutions tailored to diverse industrial environments. With extensive project experience and rigorous quality inspection processes, Anbixin is committed to delivering safe, efficient, and energy-saving industrial doors worldwide, helping businesses improve operational efficiency and safety.

FAQs

1. Can IoT-enabled sectional doors operate if the facility’s main network goes down?

Yes — most smart door systems are designed with local control fallback so they can still open/close and perform basic safety functions even if the wider facility network is offline. Connectivity mainly enhances remote monitoring, analytics, and integration with other systems, but the core door controller typically retains standalone functionality.

2. What additional value does IoT bring to facility energy management beyond smart doors?

IoT can tie door data to whole-building systems like HVAC and lighting. For example, sensors can detect door openings and trigger dynamic adjustments in heating/cooling or lighting to reduce waste, not just at the door but across zones in the facility. This contributes to broader facility optimization and sustainability goals.

3. How does IoT integration impact security and access control in industrial settings?

IoT doors can integrate with advanced access technologies like RFID badges, biometric scanners, or identity management systems to enforce layered security policies. These systems log entries and exits and can trigger alerts for unauthorized access attempts, elevating overall site security beyond mechanical door locks.

4. What challenges might facilities face when adding IoT capability to existing doors?

Retrofit IoT deployments can encounter compatibility and integration issues with legacy building management systems. This includes differences in communication protocols, data formats, and network constraints. Planning for middleware or gateways to bridge systems can help mitigate this.

5. Does IoT adoption require new skills or roles within facility management teams?

Yes — implementing and maintaining IoT-enabled doors can require new technical competencies, such as data interpretation, network security awareness, and system configuration. Facilities may need to train existing staff or involve IT specialists to support connected infrastructure and maximize ROI.

Other Industrial Doors You May Like

English

English Español

Español русский

русский tiếng việt

tiếng việt