Industrial entrances often come down to two overhead lifting systems: tilt doors and sectional doors. Both save floor space by rising vertically, both support automation, and both serve warehouses, loading bays, and high-traffic facilities. Yet their engineering, daily performance, and long-term ownership reveal sharp contrasts. Let's compares the two systems across design, space requirements, insulation, wind resistance, safety, operation, and suitability. By the finish, you’ll hold a clear decision framework and the exact questions to ask any supplier.

Core Mechanics – Monolith vs Articulated Panels

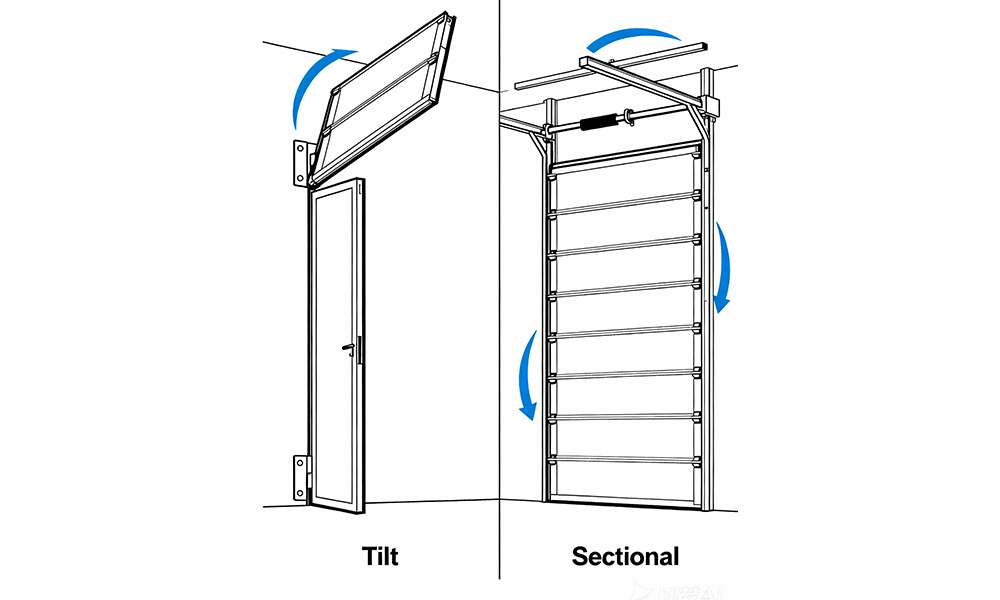

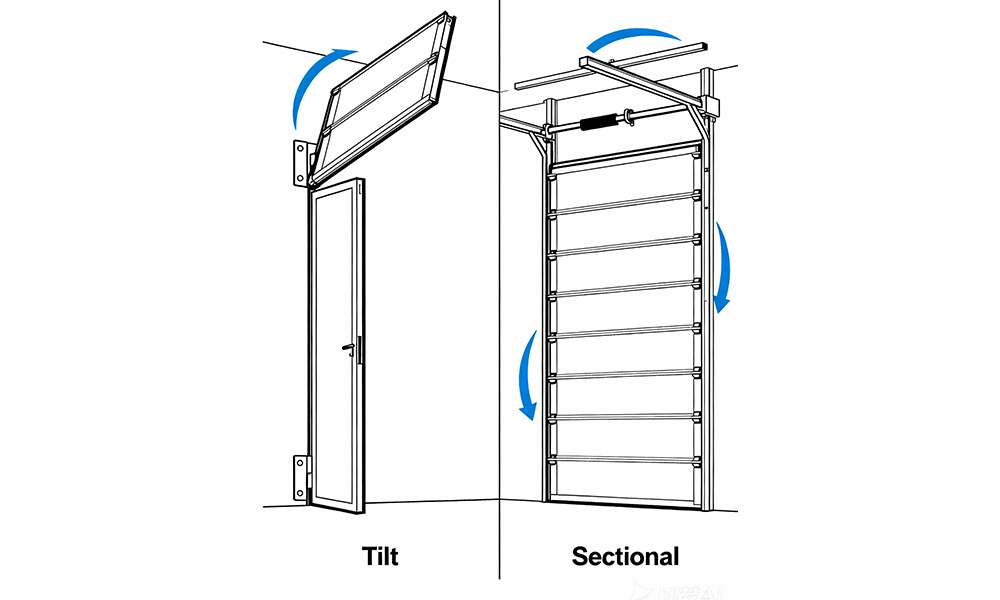

A tilt door consists of one rigid panel that pivots on lateral arms. Activation swings the bottom edge outward while the top tilts inward until the panel rests horizontally beneath the ceiling. The motion creates a temporary canopy outside the opening.

In contrast, an industrial sectional door comprises multiple horizontal panels connected by hinges. Each panel rolls along vertical tracks, then transitions smoothly onto horizontal ceiling tracks. The door remains flush with the building facade throughout the cycle.

The single-panel tilt design simplifies manufacturing yet demands generous clearance. The segmented sectional approach distributes stress across hinges and rollers, enabling larger spans and tighter spatial constraints.

Space Requirements – Headroom and Protrusion

Tilt systems require headroom equal to the full door height plus an additional margin for the pivot arc. The outward swing also projects up to one metre beyond the opening during operation, complicating tight loading docks or pedestrian zones.

Industrial sectional doors need only 450–600 mm of headroom for standard lift configurations. Low-headroom track kits reduce this to 200 mm by mounting springs at the rear. Zero external protrusion keeps the doorway clear for forklifts and weather protection.

Facilities with mezzanines, cranes, or low ceilings often find sectional geometry the only viable option without structural rework.

Thermal Performance – Insulation That Impacts Bills

Energy regulations increasingly scrutinise heat loss through large openings. Tilt doors typically offer single-skin or thin foam-filled panels, resulting in higher thermal transmittance. The continuous panel creates fewer joints but also fewer opportunities for thick insulation.

Industrial sectional doors sandwich polyurethane foam between steel skins in 40 mm or 80 mm thicknesses. Individual panels seal tightly at each horizontal joint with rubber gaskets, minimising air leakage. The modular construction allows consistent insulation density across the entire surface.

Cold-storage operators and temperature-controlled warehouses benefit from the industrial sectional doors’ superior U-values and reduced condensation risk on the inner face.

Wind Resistance – Structural Integrity Under Load

High wind zones demand certified resistance classes. Tilt doors rely on the rigidity of the single panel and the strength of pivot arms. Reinforcement kits can improve performance, but the cantilevered design inherently limits maximum wind ratings.

Industrial sectional doors distribute wind pressure across multiple panels and track supports. Vertical rails anchor directly to the structure at frequent intervals, creating a lattice of load paths. Thicker panels and optional stiffeners routinely achieve higher wind classes without custom engineering.

Coastal or exposed sites gain peace of mind from sectional systems’ engineered redundancy.

Safety Systems – Protecting People and Property

Modern standards mandate multiple failure safeguards. Tilt doors expose pivot hinges and tension springs on the exterior of the arms, complicating finger-pinch protection. Spring or cable failure risks the entire panel dropping as a single unit.

Industrial sectional doors conceal hinges between panels and integrate spring-break devices and slack-cable brakes as standard. Bottom-edge pressure sensors reverse instantly on contact. The segmented structure means a single panel failure does not collapse the whole door.

High-traffic environments with mixed pedestrian and vehicle flow favour sectional safety architecture.

Operational Speed and Durability

Daily cycle counts separate occasional-use doors from logistics workhorses. Tilt mechanisms open at 0.1–0.15 m/s due to the inertia of the monolithic panel. Pivot bearings wear under frequent use, requiring regular lubrication.

Sectional doors achieve 0.2 m/s standard speed and up to 1.0 m/s with high-performance operators. However, for facilities requiring maximum throughput and security, a hard fast door is the ultimate upgrade, offering speeds up to 2.5 m/s. Springs rated for 100,000+ cycles support intensive schedules before replacement. Distribution centres measuring seconds per bay door movement calculate measurable productivity gains with these faster systems.

Aesthetics and Customisation Options

Visual impact matters for customer-facing facilities. Tilt doors present a bold, uninterrupted surface ideal for large logos or dramatic reveals. Colour matching remains straightforward across the single panel.

Sectional doors offer vision panels, full-height glazing, or perforated sections for natural light. Each panel can carry different finishes, enabling striped patterns or progressive branding. The flush closure line integrates cleanly with curtain walling.

Showrooms and retail warehouses exploit sectional flexibility to balance security with daylight.

Decision Matrix – Matching System to Site

| Priority | Tilt Door Wins | Sectional Door Wins |

|---|

| Lowest initial complexity | Yes | No |

| Minimal headroom | No | Yes |

| High daily cycles | No | Yes |

| Superior insulation | No | Yes |

| Wind-exposed location | Limited | Yes |

| Integrated pedestrian pass-door | No | Yes |

| Quiet, fast operation | No | Yes |

Note: If your facility has extreme wind loads or requires a folding mechanism rather than an overhead track, you may also want to browse our stack up doors for sale. These high-speed folding doors provide an excellent alternative for large external openings where overhead space is obstructed.

FAQs

1. Q: How long does the average tilt or sectional door last?

A: The lifespan of either tilt or sectional doors largely depends on usage, maintenance, and environment. With proper care—including regular lubrication of moving parts and timely replacement of worn components—these doors can last 15–25 years. Harsh weather, high humidity, or industrial exposure may shorten this lifespan.

2. Q: Can tilt or sectional doors be automated with modern motorized systems?

A: Yes, both types of doors can be motorized. Tilt doors usually require stronger motors due to the large single panel weight, while sectional doors often support faster, energy-efficient automated operators with remote control or smart integration. Automation also allows integration with access control systems for warehouses and commercial facilities.

3. Q: Are there soundproofing options for these doors?

A: While the article discusses insulation for temperature, soundproofing is also possible. Sectional doors can incorporate acoustic insulation panels, which reduce noise from machinery or traffic outside. Tilt doors can be fitted with thicker or layered panels, though their single-panel design limits flexibility in soundproofing compared to sectional doors.

English

English Español

Español русский

русский tiếng việt

tiếng việt